Improper Bead Problem #2: TechniqueA concave or convex-shaped bead may also be caused by using an improper welding technique. For example, a push or forehand technique tends to create a flatter bead shape than a pull or backhand technique.RemedyFor best bead shapes, it is recommended to use a push angle of 5-10 degrees.

Improper Bead Problem #3: Inadequate Work CableProblems with the work cable can result in inadequate voltage available at the arc. Evidence of a work cable problem would be improper bead shape or a hot work cable.

RemedyWork cables have a tendency to overheat if they are too small or excessively worn. In replacing the cable, consult a chart to determine size based on length and current being used. The higher the current and longer the distance, the larger the cable needed.

III. Lack of FusionIf the consumable has improperly adhered to the base metal, a lack of fusion may occur. Improper fusion creates a weak, low quality weld and may ultimately lead to structural problems in the finished product.

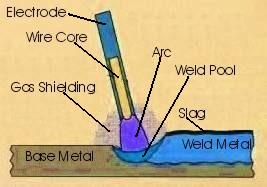

Lack of Fusion Problem: Cold Lapping in the Short Arc Transfer ProcessIn short arc transfer, the wire directly touches the weld pool and a short circuit in the system causes the end of the wire to melt and detach a droplet. This shorting happens 40 to 200 times per second. Fusion problems may occur when the metal in the weld pool is melted, but there is not enough energy left to fuse it to the base plate. In these cases, the weld will have a good appearance, but none of the metal has actually been joined together. Since lack of fusion is difficult to detect visually, it must be checked by dye-penetrant, ultrasonic or bend testing.

Remedies:To guarantee correct fusion, ensure that voltage and amperage are set correctly. If the operator is still having problems after making those adjustments, it may require a change in the welding technique. For example, changing to a flux-cored wire or using the spray arc transfer method instead. In spray arc transfer, the arc never goes out so cold lapping and lack of fusion are not issues. Spray arc welding takes place at amperages high enough to melt the end of the wire and propel the droplet across the arc into the weld puddle.

IV. Faulty Wire DeliveryIf the wire is not feeding smoothly or if the operator is experiencing a chattering sound within the gun cable, there may be a problem with the wire delivery system. Most of the problems related to wire delivery are attributed to equipment set-up and maintenance.

Faulty Wire Delivery Problem #1: Contact Tip There is a tendency among operators to use oversized tips, which can lead to contact problems, inconsistencies in the arc, porosity and poor bead shape.

Remedies:First, make sure that the contact tip in the gun is in working order and sized appropriately to the wire being used. Visually inspect the tip and if it is wearing out (becoming egg-shaped), it will need to be replaced.

Faulty Wire Delivery Problem #2: Gun Liner A gun liner, like the contact tip, must be sized to the wire being fed through it. It also needs to be cleaned or replaced when wire is not being fed smoothly.

Remedy:To clean the liner, blow it out with low-pressure compressed air from the contact tip end, or replace the liner.

Faulty Wire Delivery Problem #3: Worn Out GunInside the gun are very fine strands of copper wire that will eventually break and wear out with time. Remedy:If the gun becomes extremely hot during use in one particular area, that is an indication that there is internal damage and it will need to be replaced. In addition, be certain that the gun is large enough for the application. Operators like to use small guns since they are easy on the hand, but if the gun is too small for the application, it will overheat.

Faulty Wire Delivery Problem #4: Drive Roll Drive rolls on the wire feeder periodically wear out and need to be replaced. Remedies:There are usually visual indications of wear on the grooves of the rolls if replacement is necessary. Also, make sure that the drive roll tension is set properly. To check tension, disconnect the welding input cable from the feeder or switch to the cold feed option. Feed the wire and pinch it as it exits the gun with the thumb and forefinger. If the wire can be stopped by pinching, more drive roll tension is needed.

The optimum tension will be indicated by feeding that is not stopped while pinching the wire. If the drive roll tension is too high, it may deform the wire leading to birdnesting (tangling) and a burn back (when the arc climbs the wire and fuses the wire to the contact tip.) Make sure that the drive rolls and the guide tube are as close together as possible. Next, check the path from where the wire leaves the reel to where it enters the drive rolls. The wire must line up with the incoming guide tubes so there is no scrapping of the wire as it goes through the tube. On some wire feeders, the wire spool position is adjustable -- align it so that it makes a straight path into the tube.

Faulty Wire Delivery Problem #5: Wire Coming Off Reel and TanglingSome wire feeding problems occur because the inertia from the wire reel causes it to coast after the gun trigger is released.Remedy:If the reel continues to coast, the wire on the reel will loosen and the wire may come off or become tangled. Most wire feeding systems have an adjustable brake on the wire reel. The brake tension should be set so that the reel does not coast. By following these four guidelines, a GMAW operator new to the world of welding or even someone more experienced should have an easier time diagnosing problems before they affect the quality of the work.

Source : Lincoln Electric Company

......Read More......

By forcing the plasma gas and arc through a constricted orifice, the torch delivers a high concentration of heat to a small area. With high performance welding equipment, the plasma process produces exceptionally high quality welds. Like gas tungsten arc welding, the plasma arc welding process can be used to weld most commercial metals, and it can be used for a wide variety of metal thicknesses.

By forcing the plasma gas and arc through a constricted orifice, the torch delivers a high concentration of heat to a small area. With high performance welding equipment, the plasma process produces exceptionally high quality welds. Like gas tungsten arc welding, the plasma arc welding process can be used to weld most commercial metals, and it can be used for a wide variety of metal thicknesses. Shielding is obtained from a blanket of granular flux, which is laid directly over the weld area. The flux close to the arc melts and intermixes with the molten weld metal and helps purify and fortify it. The flux forms a glasslike slag that is lighter in weight than the deposited weld metal and floats on the surface as a protective cover. The weld is submerged under this layer of flux and slag- hence the name submerged arc welding. (Robot Welding dot com)

Shielding is obtained from a blanket of granular flux, which is laid directly over the weld area. The flux close to the arc melts and intermixes with the molten weld metal and helps purify and fortify it. The flux forms a glasslike slag that is lighter in weight than the deposited weld metal and floats on the surface as a protective cover. The weld is submerged under this layer of flux and slag- hence the name submerged arc welding. (Robot Welding dot com)

Welding can be done anywhere… outdoors or indoors, underwater and in outer space.

Welding can be done anywhere… outdoors or indoors, underwater and in outer space. They are also involved in bulldozers, cranes, material handling equipment, food-processing machinery, papermaking and printing equipment, textiles, and office machinery.

They are also involved in bulldozers, cranes, material handling equipment, food-processing machinery, papermaking and printing equipment, textiles, and office machinery. The mining, oil extraction, and gas extraction industries form yet another group. A large portion of the work involves drilling and extracting oil and gas or mining of ores, stone, sand and gravel.

The mining, oil extraction, and gas extraction industries form yet another group. A large portion of the work involves drilling and extracting oil and gas or mining of ores, stone, sand and gravel. Public administration employs welders to perform maintenance welding that is done on utilities, bridges, government armories and bases, etc. Yet another group involves wholesale and retail establishments. These would include auto and agricultural equipment dealerships, metal service centers, and scrap yards.

Public administration employs welders to perform maintenance welding that is done on utilities, bridges, government armories and bases, etc. Yet another group involves wholesale and retail establishments. These would include auto and agricultural equipment dealerships, metal service centers, and scrap yards.