The heat-affected zone (HAZ) is the area of base material, either a metal or a thermoplastic, which has had its microstructure and properties altered by welding or heat intensive cutting operations. The heat from the welding process and subsequent re-cooling causes this change in the area surrounding the weld. The extent and magnitude of property change depends primarily on the base material, the weld filler metal, and the amount and concentration of heat input by the welding process.

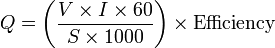

The thermal diffusivity of the base material plays a large role—if the diffusivity is high, the material cooling rate is high and the HAZ is relatively small. Alternatively, a low diffusivity leads to slower cooling and a larger HAZ. The amount of heat inputted by the welding process plays an important role as well, as processes like oxyfuel welding use high heat input and increase the size of the HAZ. Processes like laser beam welding and electron beam welding give a highly concentrated, limited amount of heat, resulting in a small HAZ. Arc welding falls between these two extremes, with the individual processes varying somewhat in heat input. To calculate the heat input for arc welding procedures, the following formula is used:

where Q = heat input (kJ/mm), V = voltage (V), I = current (A), and S = welding speed (mm/min). The efficiency is dependent on the welding process used, with shielded metal arc welding having a value of 0.75, gas metal arc welding and submerged arc welding, 0.9, and gas tungsten arc welding, 0.8.

Weman, Klas (2003). Welding processes handbook. New York: CRC Press LLC. ISBN 0-8493-1773-8.

1 comment:

what is the theoretical value generally for the MIG welding as per handbooks

Post a Comment